1

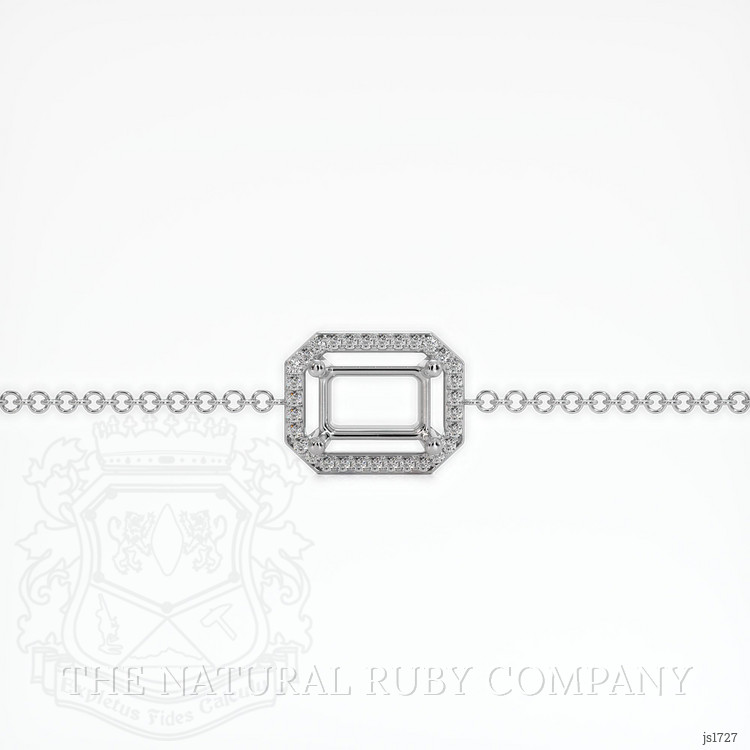

Choose your setting

2

Choose your ruby

3

Review Your design

14K White Gold Pave Bracelet Setting

Production Time: from 21 to 35 Days

Rush service may be available upon request

Item ID: JS1727

Free shipping

Price Calculated During Next Step

Quality, Value & Heart

100% Natural Rubies

Free Shipping - Worldwide

14 Day No Hassle Return Policy

Supports Local Charities

Custom Designs Created With This Setting

Filter by

Loading data. Please wait...

Watch our process

Other Bracelets You May Like

ruby essentials

Something About Rubies

Rubies are one of the most valuable precious stones, they have been coveted for centuries by royalty, gem collectors, larger-than-life personalities, and have experienced a resurgence in popularity in recent years as a centerpiece stone for an engagement ring.

Read more about rubies